Blackhall News

Valvology: helping to harness the power of the sun

A bit of history

Blackhall Engineering first began its work in the nuclear industry during the 1950s, providing the valves for Cumbria's Calder Hall Power Station. As well as being the first to open in the UK, it was also the world's first full-scale commercial nuclear power station, producing electricity all the way through the latter half of the 20th century, until its closure in 2003.

It has been almost 20 years since a nuclear power station was built in the UK, however recent breakthroughs in the viability of nuclear fusion are leading to an exciting resurgence of the possibility of a wholly clean and virtually limitless power supply for the UK. But more on that shortly. First, it's important to look at the differences between the processes used to generate power by old stations like Calder Hall, which used fission, and those that will be employed at West Burton, Nottinghamshire, which has been selected as the home for the UK's prototype fusion plant.

The difference between 'fission' and 'fusion'

What both processes have in common is that they produce large amounts of heat to generate steam, which in turn spins a turbine to create electricity. Where they differ is how they produce the heat; nuclear fission splits an atom into two or more smaller ones, while fusion, in antonymy to the first, sees two or more atoms 'fused' together.

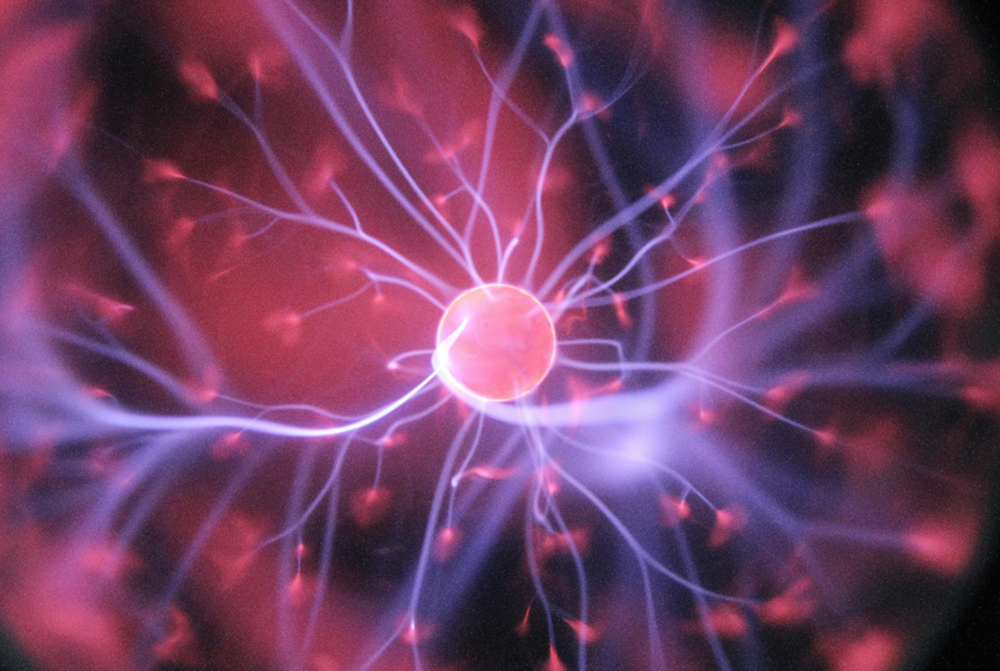

Fusion is more efficient. In fact, it produces up to four times more energy than fission (and almost four-million times more than the burning of coal, oil or gas!). It's the same process that takes place within our sun, and whilst it requires enormous amounts of heat in order to overwhelm the forces that would otherwise polarise the two atoms, the process is far cleaner. In fact, provided the correct atoms are chosen, it produces very little, if any, radioactive waste, and as for carbon emissions, they're completely eliminated. In fission, on the other hand, the splitting of atoms produces many radioactive particles and therefore lots of radioactive waste, the disposal of which presents a complicated problem when it comes to the end of the fuel's life.

There is also, in the case of fission, the problem of chain reactions. A nuclear chain reaction is when one singular nuclear reaction causes an average of one or more subsequent reactions. This series, or chain, of reactions is actually key to its success, but it requires careful control. If allowed to escalate, there is the possibility of a self-propagating series of further reactions that can quickly get out of control. In other words, there is the risk of nuclear meltdown, and perhaps the most infamous example of this would be the 1986 disaster at Chernobyl.

The importance of public perception

Accidents at nuclear power plants such as those at Chernobyl in Ukraine, and at Japan's Fukushima, have made the general public justifiably nervous whenever the subject of 'nuclear' comes up. Even today, as the government announces its confirmation of West Burton as the chosen ground for the UK's prototype nuclear fusion plant, it's clear that those perceptions are still firmly front of mind for a large portion of the UK. The last thing anybody wants is a repeat of Chernobyl, and so the go-to response of many to the topic of nuclear power is, understandably, 'not in my back yard!'.

Indeed, it's a troublesome and deeply embedded area of public concern that advocates of nuclear fusion must work to overcome. Add in the events currently unfolding in Eastern Europe and the implications they raise around the use of nuclear might - plus the fact that historic reactors used for sites like Calder Hall were also used to produce plutonium for the British nuclear weapons programme - and it becomes an even trickier web of perception to untangle.

But untangle we must, and it is important firstly to note that, with nuclear fusion, the risk of a meltdown is eliminated. Fusion reactors simply cannot sustain that kind of chain reaction. Instead, the amount of fuel present within a fusion reactor at any given time is only enough to sustain the reaction for a few seconds, and if any disturbance should occur - the kind that might, in a fission reactor, trigger a potential disaster - the fusion reactor cools within seconds and shuts down. What is also worth knowing, is that nuclear fusion doesn't employ materials that can be weaponised, like uranium or plutonium, which minimises the risk of nuclear proliferation.

The future is nuclear

As I mentioned already, the fusion of atoms is the process taking place within our sun. If replicable here on Earth, it has the potential to be the virtually limitless source of 100% clean energy that our planet so desperately needs.

If successfully developed at prototype sites like West Burton, not only will it supply unprecedented amounts of clean electricity for the national grid, it will also prove a game-changer in the government's movement towards a hydrogen economy. As I touched upon in our recent insight, 'Preparing for a hydrogen economy', Liquid hydrogen fuel is the fuel of the future, especially since the only by-product of its combustion is water vapour. But its degree of cleanliness and the size of its carbon footprint is, to a large extent, dependant on its means of production. Hydrogen fuel is made by running an electrical current through water - a process known as electrolysis. And while the resultant fuel is clean to burn, if the energy used to produce it in the first place comes from a non-renewable source, for example the burning of fossil fuels, it cannot be considered wholly renewable, or sustainable. This is why hydrogen fuel is generally ranked by its colour in the hydrogen rainbow, from green - currently the most sustainable and produced with no greenhouse gas emissions - to black and brown, which use coal. But the rainbow also includes pink, which refers to hydrogen produced with energy from nuclear fusion, and it is this that I believe will become the most prolific source.

In fact, I believe that in the not-so-distant future, every major city in the UK will have its own, small-scale nuclear fusion plant. After all, according to best estimates, the demand for power in the UK is set to double by 2040. And whilst the realistic means of meeting that with hydrogen is likely, at least in the mid-term, to be via a mixed-method approach - drawing on a spectrum of energy sources that includes those less sustainable than nuclear fusion - I am sure that nuclear fusion is set to be fundamental in the UK's bid to achieve net-zero by 2050.

How do we get there?

This relies on the technology being proven quickly enough, and then on the permission being granted to erect the power stations necessary to support this new infrastructure, which will itself rely on the changing of public perceptions. But I'm optimistic; West Burton is a step in the right direction, bringing yet another 'first of its kind' to the great north of the United Kingdom, and it is my hope that once the site is live in 2040, it wastes no time in proving the commercial viability of fusion energy, not only here in the UK, but on the international stage.

Blackhall's nuclear vision

For us at Blackhall Engineering, power-related services currently form about 30% of our business, and we are already 'hydrogen ready' with a fully developed hydrogen valve. But we are not planning to stop there, in fact, part of our mission statement is that we would like to drive our business to generate 50% of its revenue from new products and services over the next five years. This includes our hydrogen valve, but it will also encompass the manufacture and supply of valves for the UK's nuclear industry. In actual fact, our valves can already be found in every nuclear power plant in the UK, and this is a 'status quo' that we very much intend to maintain. To put it another way, as sites like West Burton work to prove the viability of nuclear fusion, we at Blackhall are working to ensure that the power of the sun, at the very least, is matched by the power of Valvology.