Blackhall News

How does Just-in-Time 'stack up' against a growing raft of supply chain issues?

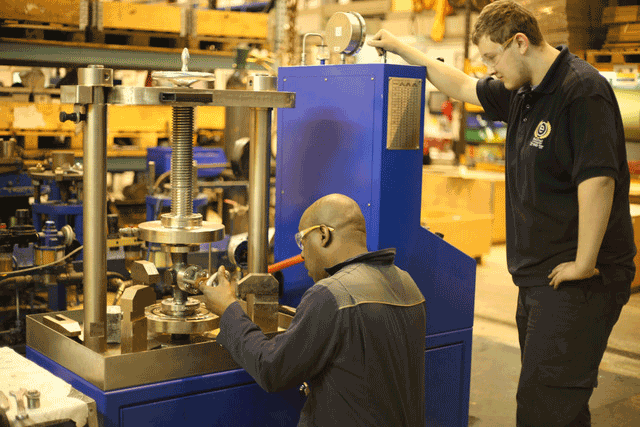

Known as 'Just-in-Time' (JIT), the workflow methodology that characterises the manufacturing process of businesses like ours, is designed to reduce flow times and costs, as well as the need to stock an excessive inventory, instead moving material 'just in time' to achieve the next stage of the process. It's a mode of operation that's adopted by small businesses and major corporations alike, but it has its limitations. These lie in the fact that it only works when each stage is closely synchronised with subsequent points in the process. As we're now seeing – in the face of growing supply chain issues being catalysed by a changing political climate, a global pandemic, and now conflict in Europe – it can easily break down.

Known as 'Just-in-Time' (JIT), the workflow methodology that characterises the manufacturing process of businesses like ours, is designed to reduce flow times and costs, as well as the need to stock an excessive inventory, instead moving material 'just in time' to achieve the next stage of the process. It's a mode of operation that's adopted by small businesses and major corporations alike, but it has its limitations. These lie in the fact that it only works when each stage is closely synchronised with subsequent points in the process. As we're now seeing – in the face of growing supply chain issues being catalysed by a changing political climate, a global pandemic, and now conflict in Europe – it can easily break down.

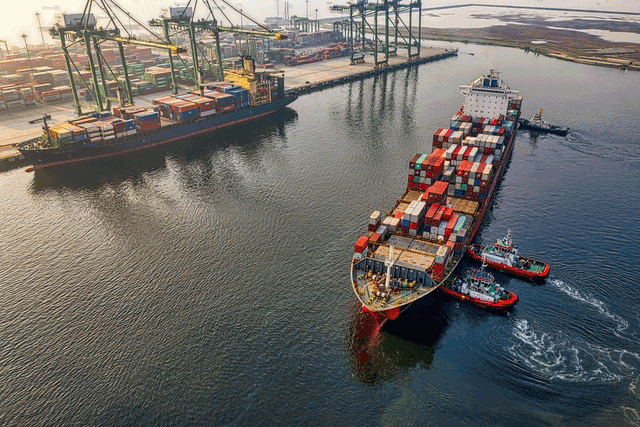

Just some of the issues that the supply chain is facing include rising costs of fuel for transportation, an extraordinary increase in prices for materials used such as copper and nickel – both key in the manufacture of critical valve components – as well as availability and lead times for other fundamental parts. Then there's Covid, which is still causing companies to have to juggle staff shortages. For clients, all of this ultimately equates to unplanned and unforeseen lateness, well outside of our control, as well as an increase in price as we attempt to mitigate against the hobbled chain of supply.

Whether or not this is a 'new normal' is difficult to predict, at least with any degree of certainty. Stability has been predicted, by the KPMG, economists and analysts within the automotive sector, within the next six to eighteen months, however this almost certainly depends on global events that, once again, are beyond our sphere of influence. The reality for those, like us, who have so-far modelled their workflow on the JIT methodology, is that we must either adapt, or expire.

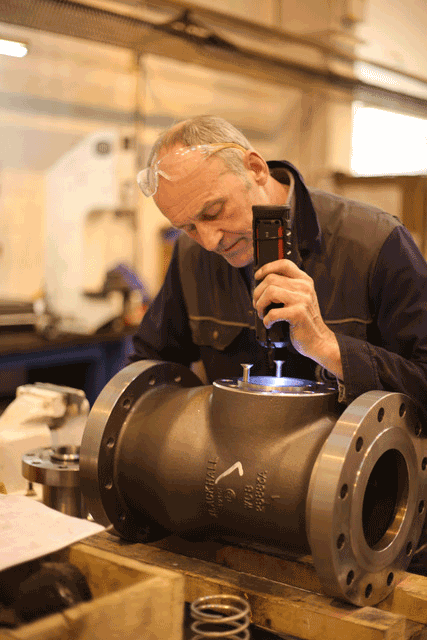

I can comfortably say that at Blackhall Engineering, we firmly intend to adapt. We are currently widening our supply chain and adopting like-minded suppliers who are demonstrably able to be agile and responsive. We are also reviewing our stocking policies in cases where key customers are willing to support us and make long-term commitments, whilst at the same time strengthening relationships with existing suppliers and managing our inventory in more creative and modular ways, to reduce lead times.

I can comfortably say that at Blackhall Engineering, we firmly intend to adapt. We are currently widening our supply chain and adopting like-minded suppliers who are demonstrably able to be agile and responsive. We are also reviewing our stocking policies in cases where key customers are willing to support us and make long-term commitments, whilst at the same time strengthening relationships with existing suppliers and managing our inventory in more creative and modular ways, to reduce lead times.

Ultimately, we are re-modelling the way in which we work to alleviate the issues of a faltering supply, the brunt of which would otherwise be borne by our clients. In the golden years of JIT, client expectations were exceptionally high, and rightly so. Until now, they were not disproportionate to the supply chain's ability to meet them. Now, as we face a struggling system, the industry-wide reality is that those same expectations have become unrealistic. But that is not the client's problem to manage; it is our responsibility as the manufacturer to ensure that strong and transparent communication prevails throughout the entire process, a philosophy in which the automotive industry is delivering a masterclass. Interestingly, the first business to develop and apply the JIT methodology was the car manufacturer, Toyota, who developed it in order to meet customer demands with minimum delays. Now that the system is breaking, it seems fitting that the same sector is once again blazing the trail forward.

Just as we are having issues with the supply of copper, nickel and other key parts, within the automotive sector, there is an ongoing, international crisis affecting the supply of the 'legacy' chips (semiconductors) required to make most modern vehicles. Due to their low value, the companies that make the chips simply aren't interested in doing so, and the new factories which are being built to service the demand are not due to come on stream until 2024/25 – namely Taiwan Semi-Conductor Co, Samsung in Texas, and Toshiba in Japan. Further compounded by rising fuel costs which are putting upward pressure on all manufacturers, the backlog of cars waiting to be made is only set to grow, and when you consider that the sector accounts for just 5% of the industry, the issue becomes all the more poignant.

Just as we are having issues with the supply of copper, nickel and other key parts, within the automotive sector, there is an ongoing, international crisis affecting the supply of the 'legacy' chips (semiconductors) required to make most modern vehicles. Due to their low value, the companies that make the chips simply aren't interested in doing so, and the new factories which are being built to service the demand are not due to come on stream until 2024/25 – namely Taiwan Semi-Conductor Co, Samsung in Texas, and Toshiba in Japan. Further compounded by rising fuel costs which are putting upward pressure on all manufacturers, the backlog of cars waiting to be made is only set to grow, and when you consider that the sector accounts for just 5% of the industry, the issue becomes all the more poignant.

So what are manufacturers doing to mitigate this? Companies within the sector are now quoting the time in which buyers can expect to receive their cars within an accuracy of months, and because this is communicated to them with honesty and transparency, buyers are happy to accept. This, I believe, is the model on which the future of our industry will be built, at least in the mid-term. In the face of inevitable change, there is now an urgent need to be agile; to keep in touch with the wider environment and remain in daily discussion with the supply chain, all of which Blackhall is embracing as a necessity.